YH93 Series

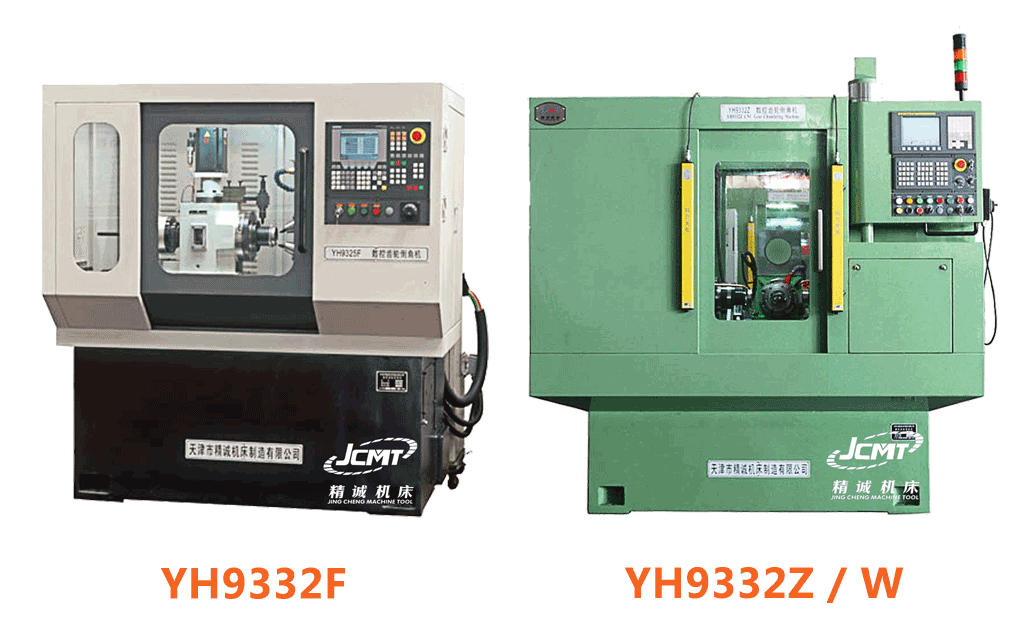

1.YH9332F CNC Gear Chamfering Machine

YH9332F is vertical layout two-axis CNC machine, which adopts interval indexing、continuous process theory. The machine adopts two end edge chamfering cutters to machining end face point angle、crown angle, in addition also can use one special chamfering cutter to machining heavy-duty internal gear of end surface round angle.

The machine have following features: two CNC axes are workpiece spindle and workpiece feed spindle, the workpiece rotation adopts servo motor to drive high-precision,dual-lead indexing worm gear. The feed motion adopts servo motor to drive ball screw pair. The cutter support is vertical layout with two cutter spindle structure, the motor is direct connected, and the speed of cutter spindle adopts frequency

conversion stepless speed adjustment. The machine high efficiency, stable performance,adjustment is easy; applicability range is wide,good quality characteristics.

Parameter table:

2.YH9332W CNC Gear Chamfering Machine

YH9332W is a CNC universal machine with threeaxis,which adopts continuous process theory. The machine adopts one chamfering cutter to machining surface point angle and crown angle.

The machine has following features: three CNC axes are workpiece spindle; workpiece headstock feed spindle and cutter headstock horizontal movement spindle, which are controlled by servo motor. The workpiece spindle is linkage with workpiece feed spindle during machining process. the rotation of workpiece adopts servo motor to drive high-precision,dual-lead indexing worm gear. The feed motion adopts servo motor to drive ball screw pair. Cutter spindle uses import high precision spindle unit, and the speed of cutter spindle adopts frequency conversion stepless speed adjustment, frequency motor is driven by cog belt. The machine high efficiency, stable performance,adjustment is easy; applicability range is wide, good

quality characteristics.

3.YH9332Z CNC Gear Chamfering Machine

YH9332Z is a CNC universal machine with three-axis, which adopts continuous process theory. The machine adopts one chamfering cutter to machining surface point angle and crown angle,special suitable for shaft gear.

The machine has following features:three CNC axes are workpiece spindle; cutter headstock longitudinal feed spindle and horizontal movement spindle, the workpiece spindle is linkage with cutter headstock longitudinal feed spindle during machining process. The rotation of workpiece adopts servo motor to drive highprecision,dual-lead indexing worm gear. The feed motion adopts servo motor to drive ball screw pair. Cutter spindle uses import high precision spindle unit, frequency motor is driven by cog belt. and the speed of cutter spindle adopts frequency conversion stepless speed adjustment.The machine high efficiency, stable performance,adjustment is easy; applicability range is wide,good quality characteristics.

Parameter table:

The YH93 series CNC gear chamfering machine is mainly designed for gear chamfering in gearbox and synchronizer of automobile, tractor and ship industries, particularly suitable for mass production batch demand.

Design sketch:

086-022-24981179

086-022-24981179